WHY CHOOSE US?

Hydromechanic Machine Company’s Key Features :

Industrial 4.0 :

Industry 4.0 allows you to automate operations, reduce costs, and make more precast decisions. A smart and autonomous system fuelled by data and machine learning allows the efficient planning, monitoring, and controlling of the machinery and production in real-time.

With the use of advanced technologies such as sensors and intelligent machines, it is possible to monitor and analyse data in real-time, leading to improved decision-making, greater productivity, and better resource utilization.

8 Point GIB Guiding system :

8-Point Gib Guided Press provide accurate guiding of moving platen/slide with extra stability to resist any deflection under different load conditions. With the 8-Point Gib Guided Slide, they operate at high speeds, with high level of precision.

8-point Guidance system with self-lubricating, graphite-impregnated bronze wear strips to provide the most precise level of ram guidance.

And this Guiding system with replaceable phosphors, bronze material and brass material. Which gives better accuracy with slide for machine.

With the 8-Point Gib Guided Slide, they operate at high speeds, with high level of precision. This type of guiding system is easy to maintain and also easy to set.

Servo operated :

The Servo Operated Hydraulic Press has the ability to adjust the speed during the process of striking and it’s also very fast approaching, as the pressing speed and the return speed do not require a long functioning time.

Servo Operated system is generally used in numerical control machine but now a day it used in Hydraulic circuit as hybrid system. Servo is more convenient for power saving application up to 40-60% as compare to induction driven system.

A servo operated system is advance technology with highly precise and smooth operation of Hydraulic Press.

Logic type powerpack :

This type of Powerpack will reduce temperature and increasing ratio of hydraulic oil. And it’s also appropriate system for higher flow of oil. And it’s widely uses for hustle free and smooth operation.

Our power pack is a combination of different control, regulatory & sensing devices, And We use standard parts for powerpack which is made by YUKEN, REXROTH, ATOS, POLYHYDRON, ETC.

Hydraulic power packs are used to regulate hydraulic pressure that is required for the operation of hydraulic machinery. The logic type power pack is a type of hydraulic power pack that uses programmable logic controllers (PLCs) to control the operation of the hydraulic press. Its increase oil life and also it can reduce oil heat up ratio. This type of powerpacks are hustle free and smooth.

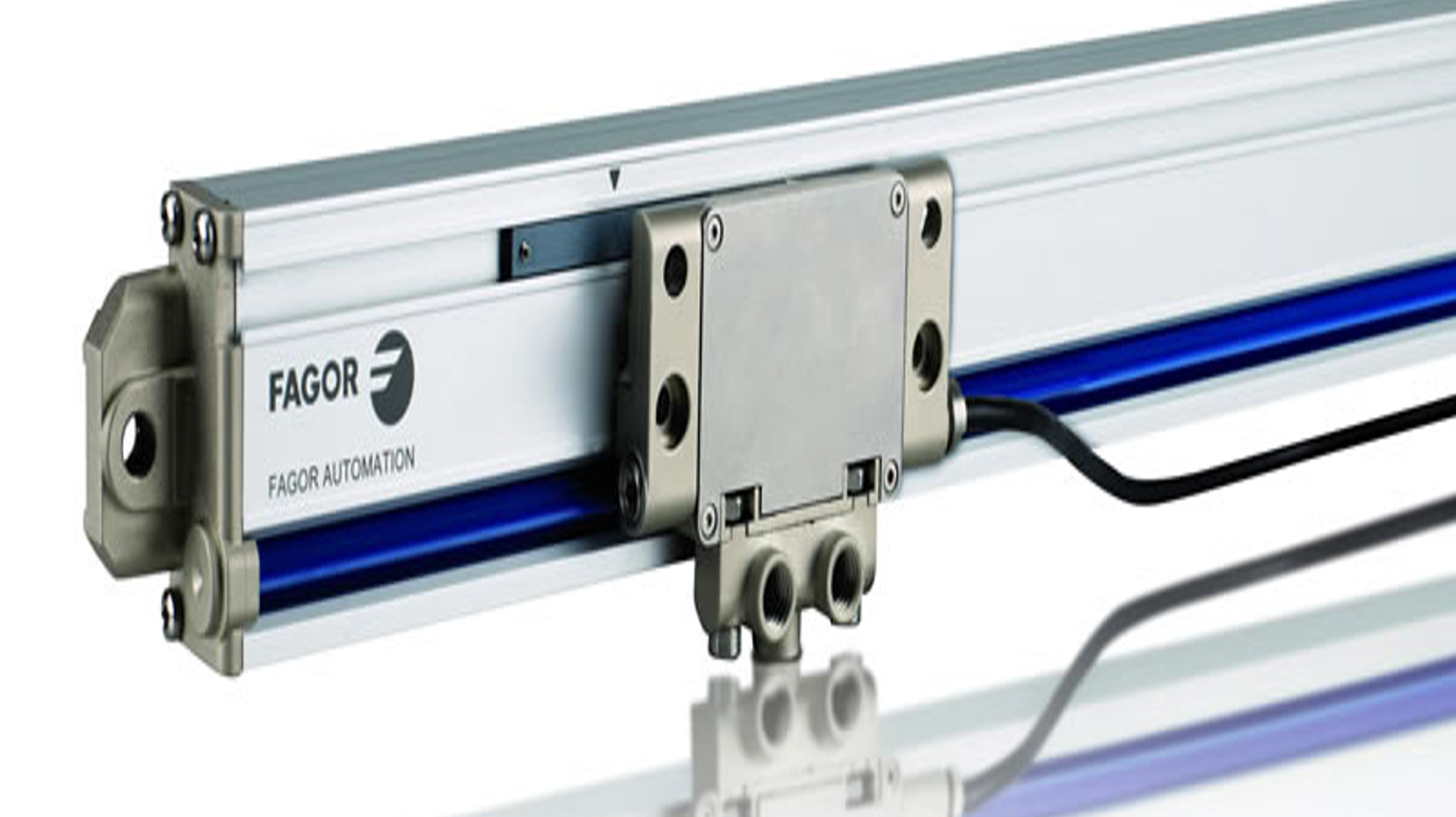

Linear Scale :

Linear Scale measures the approach and pressing length and give feedback to PLC system.

Linear scales are sensors that can measure the linear displacement of an object along a single axis. They use an encoder to track the position of the object and provide feedback to the hydraulic system's controller. This allows the controller to accurately control the movement of the press and ensure that it reaches the desired position.

By using a linear scale in conjunction with a control system, hydraulic press operators can accurately monitor and adjust the position and force of the ram during a pressing operation. This can help to ensure consistent product quality, increase production efficiency, and improve operator safety.

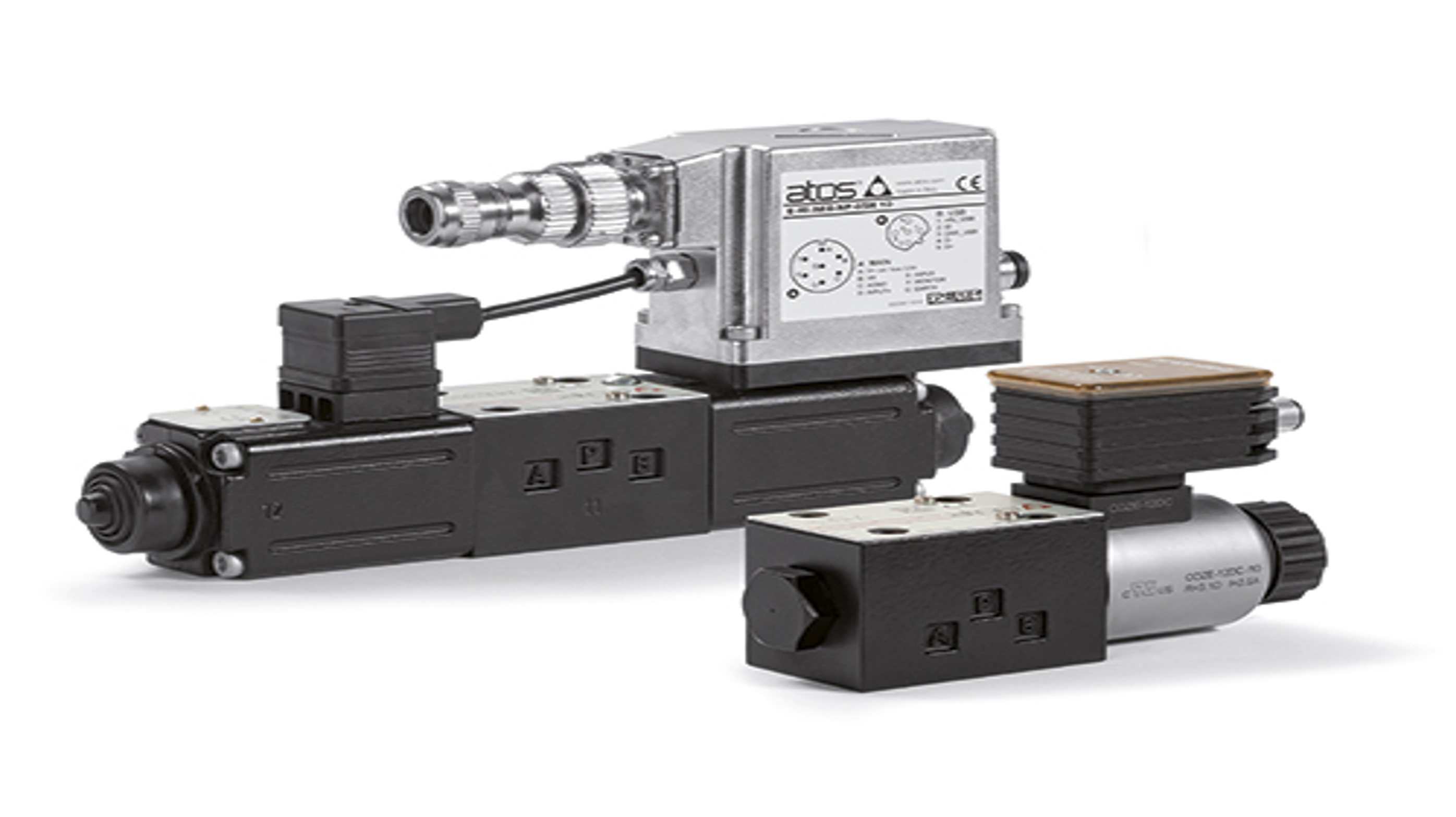

Proportional Valve :

Proportional Valves can help reduce cycle times, by quickly achieving a stable pressure. They have a fast, precise response, which will improve efficiency. They also give repeatable control and pressure output, giving an expected response each time. These valves are also called electrohydraulic valves and they have some similarities with the hydraulic servo valves like both of them are electrically controlled and to provide precise pressure and flow.

The proportional valve can control the flow of hydraulic fluid to the press cylinder, which in turn controls the speed and force of the press. By adjusting the position of the valve element in the proportional valve, the flow rate can be increased or decreased, allowing for precise control over the speed and force of the press.